Entitlements & certificates

| Certification | Scope | Certificate No. | ||

| TUV Rheinland | Fulfilling requirements according to ISO 9001:2008 | 0198 100 00409 | ||

| TUV Rheinland | Fulfilling requirements according to ISO 14001:2004 | 0198 104 00032 | ||

| TUV Rheinland | Fulfilling requirements according to ISO 45001:2018 | 01 213 1941387 | ||

| TUV Rheinland | Certificate of the Factory Production Control according to EN1090-1 Structural components and kits for steel structures to EXC3 |

2627-CPR-1090-1.84930126 | ||

| TUV Rheinland | Welding Certificate according to EN1090-2 | 1090-2.84930126 | ||

| TUV SUD Industrie Service | Fulfilling welding requirements according to EN ISO 3834-2 | TSP-3834-100.00 /

TSP-3834-343.00 |

||

| TUV SUD Industrie Service | Fulfilling pressurized equipment welding requirements according to 97/23/WE Pressure Equipment Directive | 1194/IS/2011/6000091733 | ||

| UDT (Office of Technical Inspection) |

MODERNIZATION: steam boilers, water boilers, stationary pressurized containers, non-pressurized and pressurized containers for the following materials: flammable liquids, toxic or caustic, steam pipes connecting boiler with turbo generator, technological gas pipes, technological liquid pipes; | UC-27-165-P/3-13 | ||

| UDT (Office of Technical Inspection) |

MANUFACTURING: non-pressurized and low-pressurized containers for the following materials: flammable liquids, toxic and caustic; transfer pipes; | UC-27-165-W/4-13 | ||

| UDT (Office of Technical Inspection) |

ERECTION: non-pressurized and low-pressurized containers for the following materials: flammable liquids, toxic and caustic; | UC-27-165-M/4-13 | ||

| UDT (Office of Technical Inspection) |

REPAIR: steam boilers, water boilers, stationary pressurized containers, non-pressurized and pressurized containers for the following materials: flammable liquids, toxic or caustic, steam pipes connecting boiler with turbo generator, technological gas pipes, technological liquid pipes; | UC-27-165-N/3-13 |

- To ensure the highest quality of our products and services as far as environment protection awareness we implemented in 2005 company quality management system and in 2008 company environment management system according to ISO 9001 and ISO 14001

- In July 2014 we certified also the health and safety management system according to OHSAS 18000

- In 2003 OMIS was audited by UDT (Technical Supervision Office) and entitled to manufacture, erect, modernise and repair pressurized and non-pressurized installation requiring notified body technical supervision.

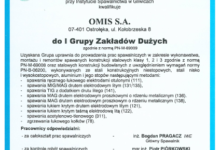

- Since 2005 OMIS has certificate of Institute of Welding – 1st class of Big Manufacturers entitling to perform welding in the area of manufacturing, erection and modernisation of all classes of steel structures according to PN-M-69009.

- In 2012 OMIS was certified as a manufacturer according to EN ISO 3834 as fulfilling all the quality requirements regarding steel structures welding of steel structures, pressurized equipment and installations according to Pressure Equipment Directive 97/23/WE

- In 2013 OMIS successfully passed the certification procedure confirming that our steel structures manufacturing process meets the EN 1090 requirements. The certificate gives OMIS the right to mark its products with CE mark.

- ISO 9001:2018

- ISO 14001:2018

- ISO 45001:2018

- UDT

- INSTITUTE

- PN-EN ISO 3834-2:2007

- PN-EN ISO 3834-2:2007

- PN-EN ISO 3834-2:2007

- 1090-1

- 1090-2